A 23-year-old college student in New Jersey has saved thousands of dollars by fixing his own teeth with a homemade aligner.

The dental entrepreneur, Amos Dudley used his university’s state-of-the-art 3D printing facility to whip up a set of clear, Invisalign-esque aligners for less than $60.

The 23-year-old wore braces as a child, but ditched them before they had lasting effects on his teeth. Years later, Amos hated his smile, so he looked into potential teeth-straightening treatments.

Being a college student, Amos’ budget had probably been blown on two-minute noodles and a six-pack of light-strength beers, leaving the prospect of a dentist appointment well out of reach.

After looking into the aligners available on the market, he noticed that the make-up of many name-brand products were similar to some of the 3D printing he had done in class.

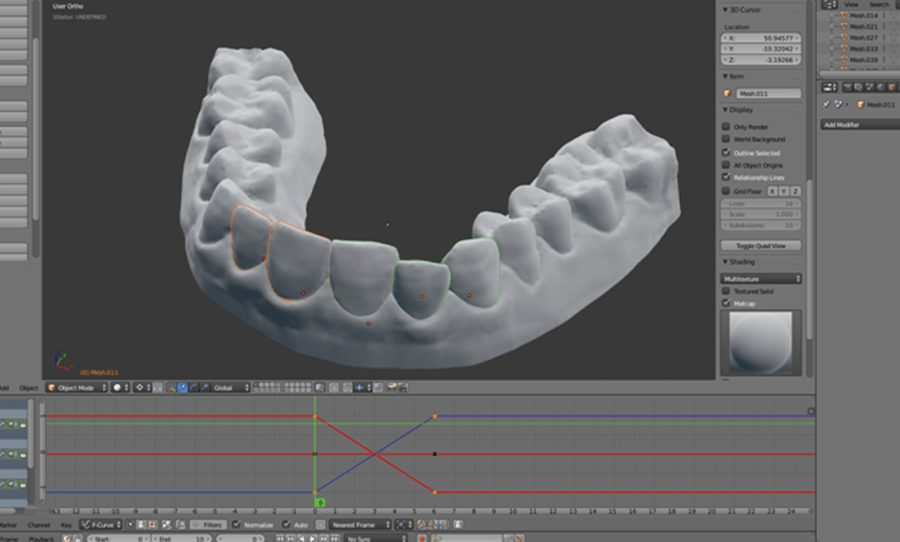

So, Amos did a bit more research, and set to work. He started by making casts of his teeth in a yogurt container, then turned the cast into a digital model using software on his computer.

The question that’s probably going through your head right now was answered by Amos on his blog. “What is to stop someone, who has access to a 3D printer, from making their own orthodontic aligners?” he wrote. “Turns out, not much!”

That’s easy enough for him to say, considering he’s spent the last few years of his life studying 3D printing. In reality, it seems really, bloody hard.

The 23-year-old had to plan every section of the mould to the exact degree, so that each tooth would be straightened without intersecting with each other.

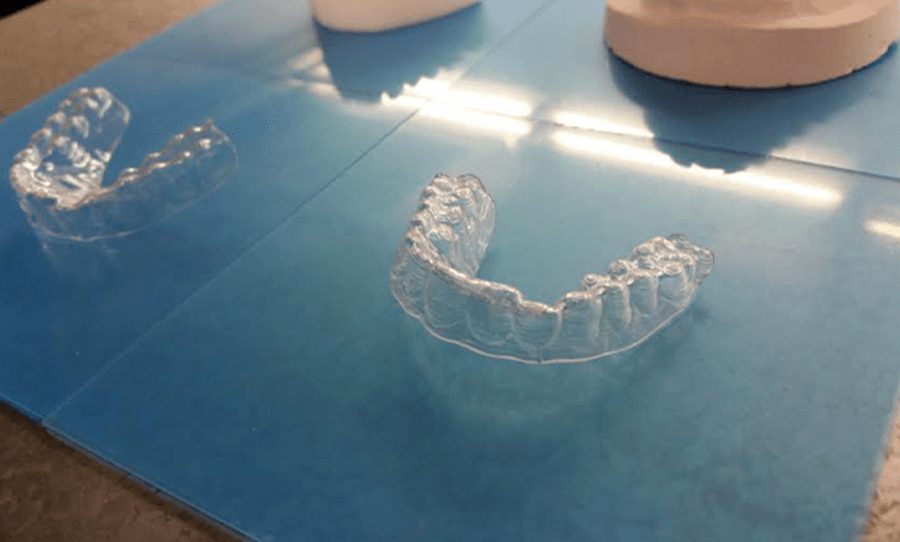

Next, Amos 3D printed the edited model of his teeth, so that he could mould an aligner around them.

His efforts seem to be successful so far. He’s been wearing the DIY aligners for 16 weeks now, only removing it to eat.

“As far as I know, I’m the first person to have tried DIY-ing plastic aligners… They’re much more comfortable than braces, and fit my teeth quite well,” Amos said. “Most importantly, I feel like I can freely smile again.”

But the undergraduate doesn’t plan on selling his creations anytime soon. Nor does he recommend the process to others, and fair enough. There’s a reason orthodontists study for 10 years before they can legally work.

That said, this guy deserves some major kudos. We could barely wrap our head around the process well enough to write about it, let alone successfully manufacture.