Our Needle in the Hay vinyl comp wouldn’t be happening if it weren’t for the legends at Zenith Records, straight up. As the only vinyl pressing facility in Australia, they’re fighting the good fight in a landscape that is falling back in love with the old format in a very big way.

As much as they’re killing it right now, it’s no easy task to get an operation like Zenith Records up and running. We recently caught up with Paul Rigby, the boss man down at the Brunwick factory, who was happy to shed some light on where Zenith came from, and where it will go from here.

What does it take to establish and run the only vinyl pressing plant in Australia? We sit down with Paul Rigby, director of Zenith Records.

HAPPY: How was the lead-up to Record Store Day? Must be just about the event of the year for Zenith.

PAUL: It’s always a big lead up to RSD, but not necessarily the mad frantic dash it perhaps has been in the past. We’ve found that our customers give themselves plenty of lead time to ensure they have stock one to two months ahead of RSD.

One of the luxuries we enjoy is that customers who’ve been offshore in the past are always allowing us the two or three month lead times they’ve needed to get stock when we’ve been able to turn records around much quicker. We were able to accomodate a lot of last minute 7” jobs, a couple of which we turned around in weeks and delivered in time.

HAPPY: Did you grab yourself any vinyl?

PAUL: I drove past a few shops on my way in to the factory to do some breakdown maintenance on the Saturday, with the intention of popping in and saying hi. I was blown away by the crowds and lack of car parking, so I just kept on driving. After all, we needed to ensure a few mechanical issues were ironed out for production on the Monday.

For us, Record Store Day never ends, there’s always a release date, a launch date or an event that simply has to have product at, so not a lot changes.

Some of my fave RSD releases I enjoyed that we did here are The Pinheads (Farmer & The Owl), Hiroshi and Claudia , reissue of an obscure 70s Australian funk/disco release that was originally a custom pressing and brought back to life through Votary/Northside Records. There were any number of great vinyl releases we did in the lead up to RSD but weren’t necessarily RSD exclusives which we’ve enjoyed over the past few months.

HAPPY: Zenith is the only dedicated vinyl pressing facility in Australia. Can you talk about the origins of the project and why you think nobody else has felt game enough to launch something similar?

PAUL: We pretty much took over the only operating vinyl rig in Australia, so the hard work was done in the 1990s when Corduroy put the backbone of the plant together when presses were being shipped to the scrap yard. We’ve overhauled the pre-existing equipment and added additional presses, boilers, and galvanics so that what we have produces world class product.

While at times, prior to 2013 under different ownership, Zenith perhaps had not been the most market orientated operation, it had become easier for many customers to source their pressings with greater certainty from offshore plants. Moving Zenith to its present location and concentrating on continual improvement are what we’ve been about since that time.

At the time I took over, I had at my disposal the plant and equipment of a pressing plant right here in Melbourne – it just needed the dedication, hard work and application to bring it up to being a reliable operation. To start from scratch without having access to pre-existing equipment, until recently meant that old presses needed to be sourced from offshore and overhauled to the exacting specifications to ensure production.

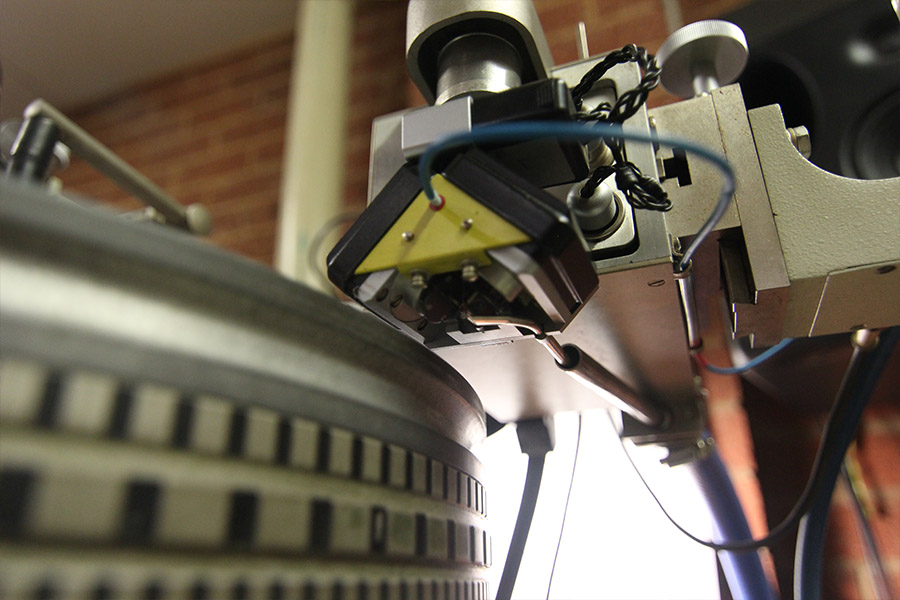

With every other plant and interested party across the globe scrambling to access old gear, it’s only been in the last two years that new pressing equipment has become available and the investment required to set up from scratch is a lot more considerable. With the Zenith plant, we also inherited the “secrets of the grail”, the procedures involved for all steps of the process, from cutting to silvering and plating and press operation, which we have enhanced and modified to get the best out of each step. We’re also fortunate enough to have our own Neumann VMS70 cutting lathe that allows us to carry out all cutting in house, unlike many plants in the US who rely on third parties to do so.

While there are companies at present making new presses and plating equipment, there are no new cutting lathes being built which has meant that our lathe has almost doubled in value since we valued the plant four years ago.

The big issue facing prospective investors looking at getting into vinyl pressing would be the lack of certainty of a return on an investment in this game while there are many other lucrative ventures that money would be better spent. Run sizes locally are rather small compared to rest of the world and a lot of the large titles are shipped into Australia which have been pressed in bigger numbers, a fraction of which shipped out here for local demand.

Then, there’s the perennial question of “How long till the vinyl bubble bursts?”

HAPPY: What’s the current setup look like at Zenith? How many presses are you running and are there any more on the way?

PAUL: We’re currently running three presses – two 12” presses and one 7” press. We have two automatic presses awaiting commissioning and some parts that are currently in the UK. We are looking at installing another three semi-automatic presses later this year so we can offer 10” records and picture discs. We will also be adding an extra four galvanic cells to lift our plating output.

HAPPY: How have the last few years, given vinyl’s growing popularity, affected Zenith Records?

PAUL: Its allowed us to ensure full time employment of eight people and continually improve what we do and how we do it. It’s also meant that we’ve had to ensure that our presses are in continuous operation and any money gained has gone back into further investment.

Last year we installed a new steam boiler to allow us to have sufficient steam pressure (record pressing relies on steam heating the plates under pressure and cooled water to set each record) to reduce our cycle times and have reserve steam pressure to put more presses in line. To get the pressure balances right meant that we fell behind with output and put in a lot of hours to get this right. While the back end of our operation (steam and water) are common industrial installations, the exacting nature of our requirements and limited tolerances are rare in other industries.

We found ourselves having to eliminate numerous variables, many unrelated to resume consistency and ensure we had good records pressed. While we were experiencing delays, and turnarounds did extend, we were still delivering faster than offshore.

HAPPY: Where do you see the world of vinyl after a few more years of upwards growth? How will artists and facilities like Zenith have to adapt to the changing market?

PAUL: When I embarked on getting Zenith on its feet again, we envisaged a five year window of the popularity and demand that we’re currently enjoying. That was four years ago. There are always indicators to suggest that maybe vinyl has peaked and that the increase in sales figures of vinyl records has more to do with more accurate reporting of actual sales.

When a plant receives an email from a larger offshore plant looking for overflow work (work that we need a hand with if our capacity is stretched) then it’s an interesting scenario in that the larger plant has more capacity than it has orders for, which is something not heard of until recently. We’re presently discussing moving our cutting room to a larger premises that will allow us to offer live-to-lacquer recordings. This was something Corduroy used to do and a thing that inspired Jack White, when The White Stripes toured in the late 90s and did a recorded gig at the Corduroy plant. Unfortunately the single never saw the light of day, but there were a few others that saw release and they sound fantastic.

We also (quite by a stroke of luck) acquired a dedicated Studer tape machine with a tape head configuration designed specifically for working in tandem with a cutting lathe for cutting directly from tape. Within a couple of months we’ll be able to accept 1/4” tape masters for cutting and cater to the purists who wish to bypass the digital realm altogether.

HAPPY: Being based in Brunswick, you’re pretty close to the beating heart of vinyl in Australia. Has your location played a big part in Zenith’s identity and growth?

PAUL: I wouldn’t say so. Being in Brunswick means that many of our Melbourne customers enjoy the convenience of our proximity, but we are supplying records Australia-wide as well as doing lots of exports to Malaysia, Chile, Indonesia, Singapore, Canada and the US.

We’d all rather be coming to work in Brunswick that trekking out to the outer suburbs to a cheaper industrial location. Most of our employees live nearby and either walk or ride bikes to work. We’ve been lucky with our lease as our landlord loves what we do and has been fully supportive of our tenure.

HAPPY: Were you involved in the Melbourne/Australian music scene before becoming involved in Zenith? In what capacity?

PAUL: I’d been involved in CDs, digital media and printed packaging prior to taking on Zenith. Initially I cut my teeth with cassettes in the 90s, then ran a CD plant, then went into brokering discs and organising printed packaging.

In the last company I worked, we set up an arrangement with a European record manufacturer as the Australian agent, which was fun but fraught owing to the lead times, the language barrier and the problem with how to resolve any problems once stock arrived. For me, the need for a functional Australian record pressing operation was badly needed and the opportunity to put some hard work in making this a reality with the by and large, under utilised Zenith plant was a no brainer.

The logistics of setting up at a new site was no mean feat and it involved 12-14 hour days, six to seven days per week for four months.

HAPPY: Being a bit of a singularity in Australia, do you find the artists often want to involve themselves in or witness the pressing process?

PAUL: Sometimes – customers will often want to attend cutting or take pics or videos of their jobs being pressed.

HAPPY: It would be wrong to finish this interview without asking about your own record collection. Have you been a long time collector and do you have any all-time treasures?

PAUL: Not really. I still have vinyl I bought in the 80s which I’ll still give a spin. When CDs came in, I kept buying vinyl but I would not really call myself a collector, I just never stopped buying vinyl and found that when everyone was trading in their record collections and replacing it with CDs, there suddenly was a lot of hard too get stuff up for sale in the 90s.

The thing was, back when I was teenager all my money from the various part time jobs I had went on buying records. Now I get a whole of satisfaction by being involved in making records as well as having a budget to buy new records for purely “research reasons” to always keep a feel for the quality (and often poor quality) of new pressings in the market.

You can check out Zenith Records on Facebook or their website.

Needle in the Hay is a vinyl competition targeting the next wave of musical talent in Australia (and now NZ). Enter here for the chance to win 250 copies of your EP or album printed at Zenith Records.